Value Stream Management (VSM) is a leadership and technical discipline that enables the maximum flow of business value through the end-to-end solution delivery life cycle.

Delivering digitally enabled solutions in today’s enterprises can be complex, spanning numerous functional boundaries and spawning countless cross-team dependencies. This can result in a fragmented delivery process with clunky handoffs, breakdowns in communication, and substantial delays.

The purpose of VSM is to bring order to this chaos so that value-producing work can flow smoothly and continuously across the organization. The key to succeeding with VSM in SAFe is applying Lean Thinking principles to every value stream.

Details

In SAFe, Lean thinking is the foundation of VSM. Lean is an extensive body of knowledge aimed at improving operational efficiency by eliminating causes of delay. Lean thinking is anchored in the following five principles. [1]

- Precisely specify value by specific product

- Identify the value stream for each product

- Make value flow without interruptions

- Let the customer pull value from the producer

- Pursue perfection

The remainder of this article describes each of the principles, how they enable VSM in SAFe, and who in the organization is primarily responsible for applying them.

1. Precisely Specify Value by Specific Product

This first principle of Lean thinking underscores the importance of understanding customers’ needs and quantifying the value inherent in the products and services delivered to them. In SAFe, that value comes in the form of enduring Solutions—not ephemeral projects or initiatives—and is ultimately determined by the customer.

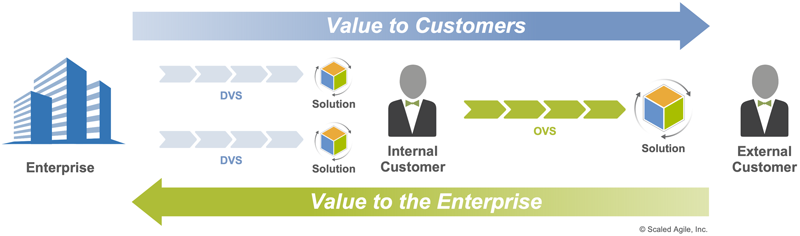

In accordance with SAFe Principle #1 – Take an economic view, VSM involves defining an overarching economic strategy for the value stream, which includes a bi-directional exchange of value for each solution delivered (Figure 1).

Digitally enabled solutions are delivered through a SAFe portfolio via one or more Development Value Streams (DVS), usually to internal customers. Those internal solutions are then used to support the delivery of market-facing solutions via Operational Value Streams (OVS). Each customer in the end-to-end flow of value derives tangible and/or intangible benefits from the solutions they receive. Likewise, value is returned to the enterprise in the form of revenue or decreased costs. Although VSM can be applied to all types of value streams, SAFe specifically applies VSM to optimize the DVS.

The process of specifying value is aided by Customer Centricity and Design Thinking. Being acutely tuned to the wants and needs of customers—and having a process to obtain continuous market feedback on solution ideas—ensures products and services deliver mutual, ongoing value.

Determining precisely how much value solutions deliver requires objective measurement. In SAFe, Key Performance Indicators (KPIs) are used to quantify the value solutions deliver to customers as well as the economic benefit returned to the enterprise.

2. Identify the Value Stream for Each Product

Once the value of their solutions has been precisely defined, organizations must identify the process by which they will develop and deliver that value to customers.

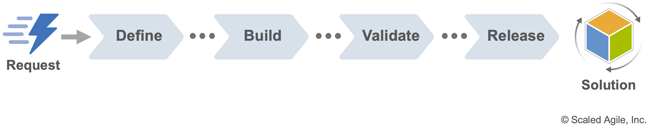

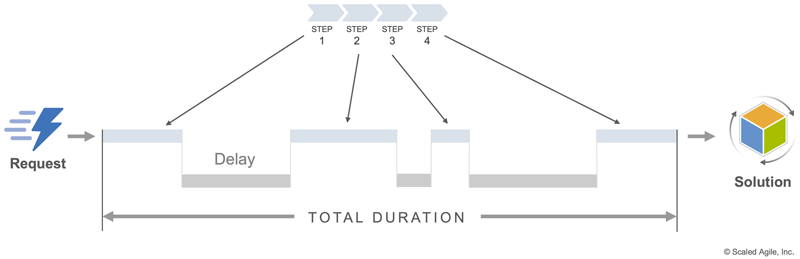

A DVS, or simply value stream in the context of this article, is the set of steps an organization executes to deliver a solution to the customer. The specific sequence of steps is unique to each value stream but generally involves defining, building, validating, and releasing functionality incrementally, as shown in Figure 2.

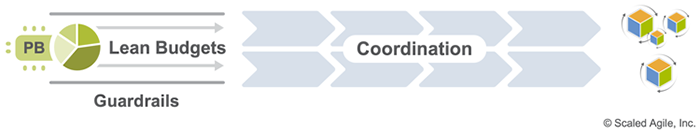

Development value streams are organized into SAFe portfolios, as Figure 3 illustrates. Each value stream delivers one or more solutions—in the form of products and services—to the customer. Budgets are allocated directly to value streams, funding the people, systems, and materials required to fully deliver those solutions.

SAFe Principle #2 – Apply systems thinking, guides the organization in identifying the entire value stream from request to release and regarding it as a single, integrated delivery system. This serves to align efforts across the organization toward managing one shared value stream as opposed to many independently managed fragments.

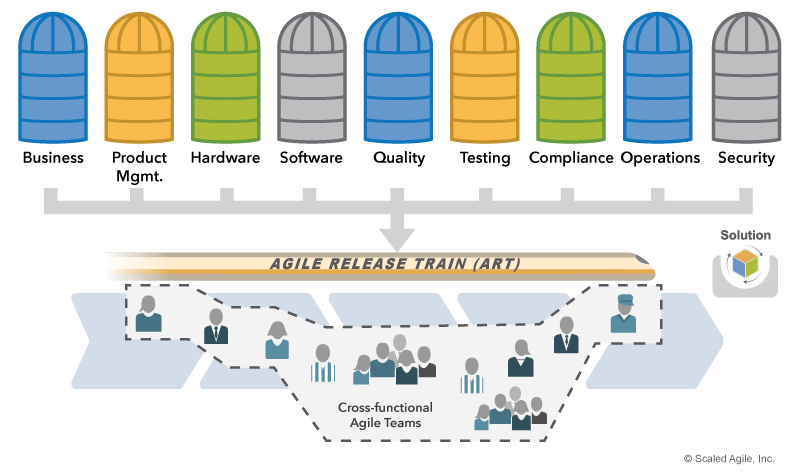

Once the value stream has been identified, everyone involved in carrying out its steps is organized around it to ensure smooth execution. As described in Principle #10 – Organize around value, this requires people with different skills to come together as a unified, enduring, cross-functional Agile Release Train (ART), as illustrated in Figure 4.

Large solutions—such as aircraft, automobiles, satellites, and medical imaging devices—typically require multiple ARTs and external suppliers to effectively realize the value stream. Solution Trains are established to organize the many hundreds, sometimes thousands, of individuals required to navigate these complex value streams.

3. Make Value Flow without Interruptions

Once value streams are identified, and teams are organized around the solutions they support, the value stream must be cleared of wasteful activities that delay solution delivery. Locating the sources of these delays is the first step toward improving value flow.

Value stream mapping accomplishes this by modeling the end-to-end sequence of activities and measuring performance at and between each step. As shown in Figure 5, value stream maps help visualize the value stream and pinpoint major delay occurrences.

The next step toward accelerating flow is identifying the root causes of these delays and applying Lean-Agile methods to correct them. Specifically, applying SAFe’s eight flow accelerators enables flow to be maximized throughout the entire value stream:

- Visualize and limit WIP

- Address bottlenecks

- Minimize handoffs and dependencies

- Get faster feedback

- Work in smaller batches

- Reduce queue length

- Optimize time ‘in the zone’

- Remediate legacy policies and practices

These are time-tested approaches to addressing flow issues. How they are best applied depends on the nature of the issue and where it occurs in the value stream.

Read this companion article for additional guidance on making value flow without interruptions.

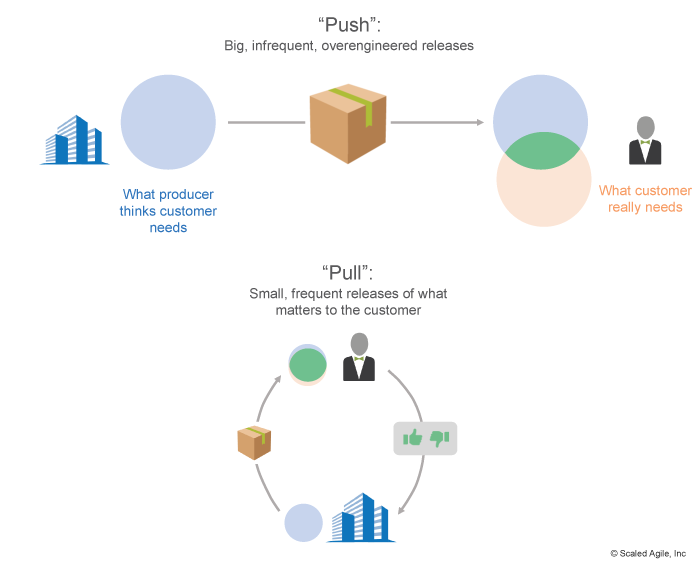

4. Let the Customer Pull Value from the Producer

Value streams must deliver the right value to the right customers at the right time. This fourth principle of Lean thinking guides organizations to deliver solutions that customers pull into market based on their actual needs, rather than pushing solutions into market based on what they think customers need (Figure 6).

Traditional, push-based delivery systems produce large, infrequent releases that typically deliver too little value too late. The solution is to create pull-based flow, where small batches of work are prioritized and delivered quickly to obtain fast customer feedback.

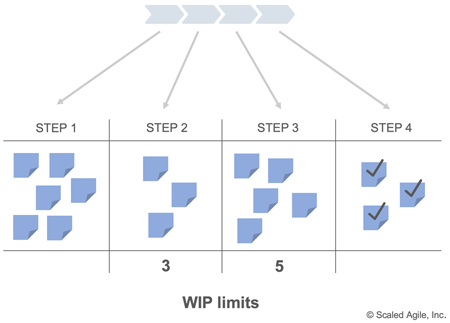

A simple yet powerful way to implement pull-based delivery is with a Kanban system. These are visual representations of the value stream (or segments of the value stream) that help regulate efficient flow through the system, as shown in Figure 7.

Kanban systems are inherently pull-based and enforce small batches through WIP limits applied at each step. SAFe encourages the use of Team, ART, Solution Train, and Portfolio Kanban systems.

Further, solutions should be architected to support pull-based flow and on-demand releases. They should be loosely coupled such that individual components and sub-systems can be changed, tested, and deployed independently, avoiding the high transaction costs and delays of ‘big bang’ change efforts. This can be accomplished by architecting for DevOps and continuous delivery using domain-driven design (DDD), containerization, and cloud-first methods. Also, feature toggles and blue/green infrastructure patterns effectively decouple deployment from release and allow functionality to be pulled into use on demand.

5. Pursue Perfection

VSM is an ongoing practice that continually optimizes the value stream in the pursuit of maximum flow and quality. Although a perfectly efficient value stream is not achievable, the constant drive for perfection is a trademark of Lean thinking and establishes a culture of continuous value stream innovation throughout the organization.

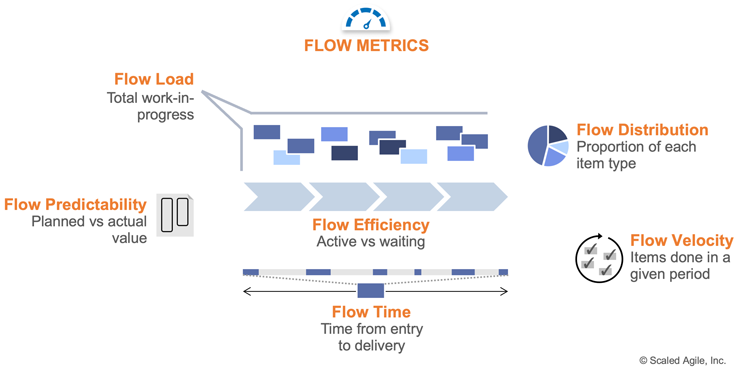

An organization pursuing delivery perfection must regularly assess its value stream against defined performance targets. Proper metrics, both quantitative and qualitative, provide a foundation for effective decision-making, replacing opinions with facts. Flow metrics (Figure 8) offer a comprehensive view of the work moving through the value stream along with how quickly, predictably, and efficiently that work is flowing. These objective measurements help to identify the precise locations of delivery bottlenecks.

In addition to tracking and optimizing flow metrics, perfection is sought via incremental, radical, and relentless improvement.

Incremental improvement, or kaizen, systematically addresses specific impediments in the value stream in short bursts. These efforts address specific pieces of the value stream at a time in a never-ending stream of targeted improvements that are informed by Iteration Reviews, Inspect and Adapt events, and periodic value stream mapping sessions. But sometimes, more dramatic, system-wide changes are required.

Radical improvement, or kaikaku, involves a significant reconfiguration of the value stream itself. This is necessary when the activities and/or people in the value stream, as they are currently organized, are not able to deliver the required solutions. The value stream must be redefined, and the people reorganized around the new flow of value. In these circumstances, organizations go through the process of identifying value streams and ARTs, replacing existing activities and re-configuring ARTs as necessary.

Organizations must continually identify inefficiencies in the value stream and make incremental and radical improvements when necessary to correct them. This persistent quest for perfection and bias for action signifies relentless improvement—a fundamental component of the Lean-Agile mindset.

Value Stream Leadership in SAFe

VSM is not easy. It entails the disciplined, perpetual application of the five principles of Lean thinking throughout each value stream. This, of course, requires time, expertise, and dedication. Who, then, is responsible for managing the value stream?

Historically, organizations have appointed a Value Stream Manager to serve in this capacity, particularly in manufacturing contexts. A prototypical Value Stream Manager has the following characteristics:

- Lean mindset – They understand the principles of Lean thinking and how to apply them to improve value stream flow.

- Business knowledge – They understand the customer needs, market forces, and compliance factors that shape product strategy and define value metrics that guide product delivery.

- Technical knowledge – They understand which products, services, and supporting tools will produce the solutions with the most business value.

- Process knowledge – They understand the sequence of activities across the organization that turns ideas into valuable solutions.

- Strategic influence – They evangelize, support, enable, and secure funding for value stream improvements.

- Tactical influence – They identify needed improvements, mobilize teams, lead change, and regularly measure results.

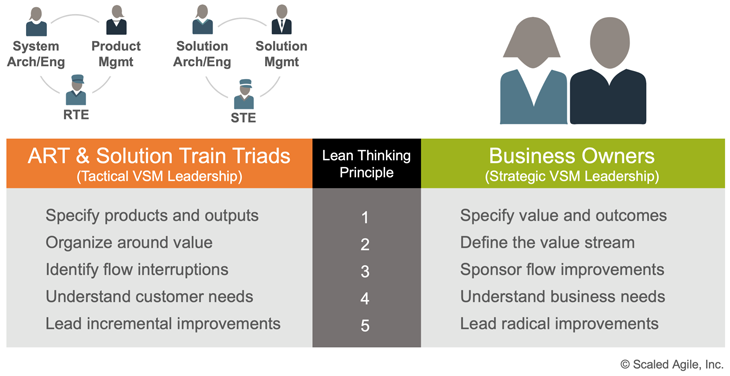

A single Value Stream Manager may suffice for small, independent value streams; however, it is unlikely that any individual possesses all the necessary characteristics at scale. Therefore, in SAFe, a few key roles have joint responsibility for managing the value stream. As illustrated in Figure 9, ART and Solution Train triads carry out the tactical, output-oriented aspects of VSM while Business Owners provide the strategic, outcome-oriented aspects. Together, they act as a team to provide the multi-faceted leadership required to manage the execution and evolution of value streams at enterprise scale.

In cases where a value stream manager has been designated, the person in this role would likely also serve as a Business Owner for one or more ARTs and assume the strategic VSM responsibilities listed above. If not, at a minimum, they would share the responsibility of managing the value stream with the individuals in these defined SAFe roles.

Triad Responsibilities

Triads align key individuals who possess business, technical, and SAFe expertise to a shared purpose of managing efficient delivery execution. Product Management, System Architecture, and the Release Train Engineer (RTE) jointly guide ART execution, while Solution Management, Solution Architecture, and the Solution Train Engineer (STE) jointly guide Solution Train execution.

Each role carries specific responsibilities within its domain of expertise—as explained by its framework article—but, together, they have the added collective duty of managing the tactical execution of the value stream. Each triad applies the principles of Lean thinking to optimize its value stream for the most desirable outputs, as measured by SAFe’s flow metrics.

Members of the triad work together, combining their strengths and spheres of influence, to define and architect solutions, technology stacks, and processes for continuous value flow; facilitate the identification of flow bottlenecks, and lead the organization through changes that accelerate value delivery.

Business Owner Responsibilities

Business owners are ultimately accountable for value stream outcomes. As such, they provide the vision, strategy, governance, and leadership alignment required to operate and change value streams in alignment with evolving business needs.

Business owners apply the five principles of Lean thinking to optimize their value streams for the most desirable business outcomes. They define the Key Performance Indicators (KPIs) that steer solution design toward the realization of tangible economic benefits. Business owners then guide and support ARTs and Solution Trains through delivery in alignment with these KPIs.

In support of relentless improvement, Business Owners sponsor major value stream improvement opportunities identified by ART and Solution Train triads. When Bottlenecks are so severe that they require radical changes to the value stream, Business Owners provide the strategic influence needed to define, prioritize, and implement systemic—sometimes disruptive—improvements that yield the greatest value to customers.

Summary

VSM is a leadership and technical discipline that enables maximum flow of business value through the end-to-end solution delivery life cycle. SAFe enables VSM through its alignment with the five principles of Lean thinking and a multitude of practices that optimize delivery efficiency across the organization.

VSM requires active, ongoing effort by leaders in the organization with business, technical, and process expertise as well as strategic and tactical influence. In SAFe, these responsibilities are shared among the ART triad, Solution Train triad, Business Owners, and Value Stream Managers (if present) to ensure effective value stream management at scale.

Original address:

Advanced Topic – Value Stream Management in SAFe

Note: Some pictures come from the Internet